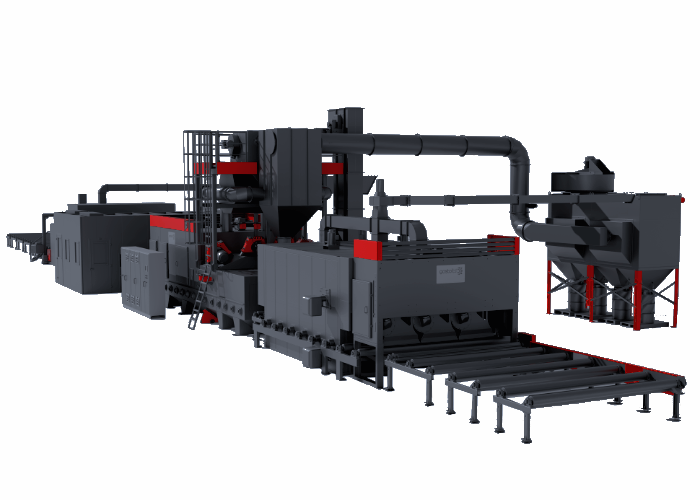

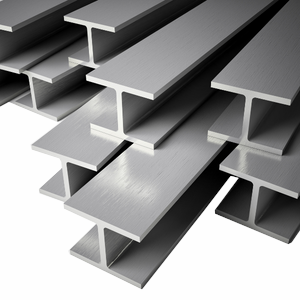

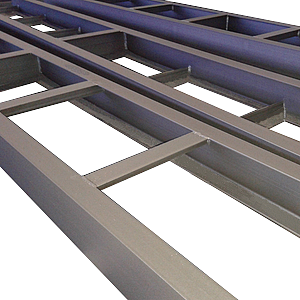

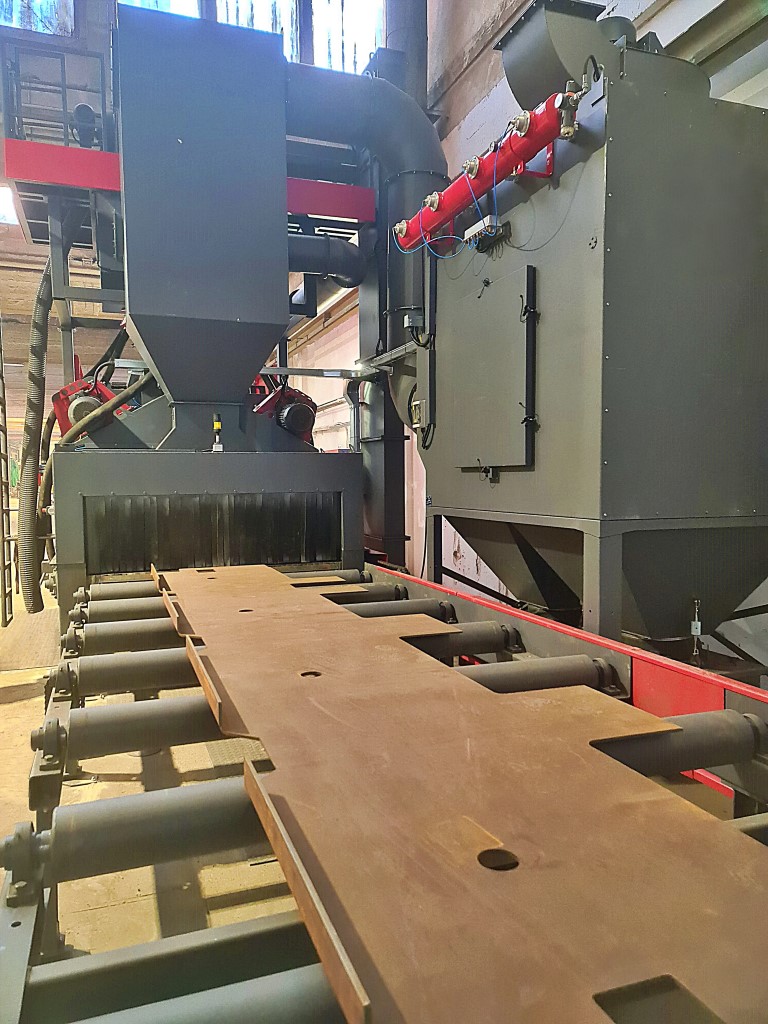

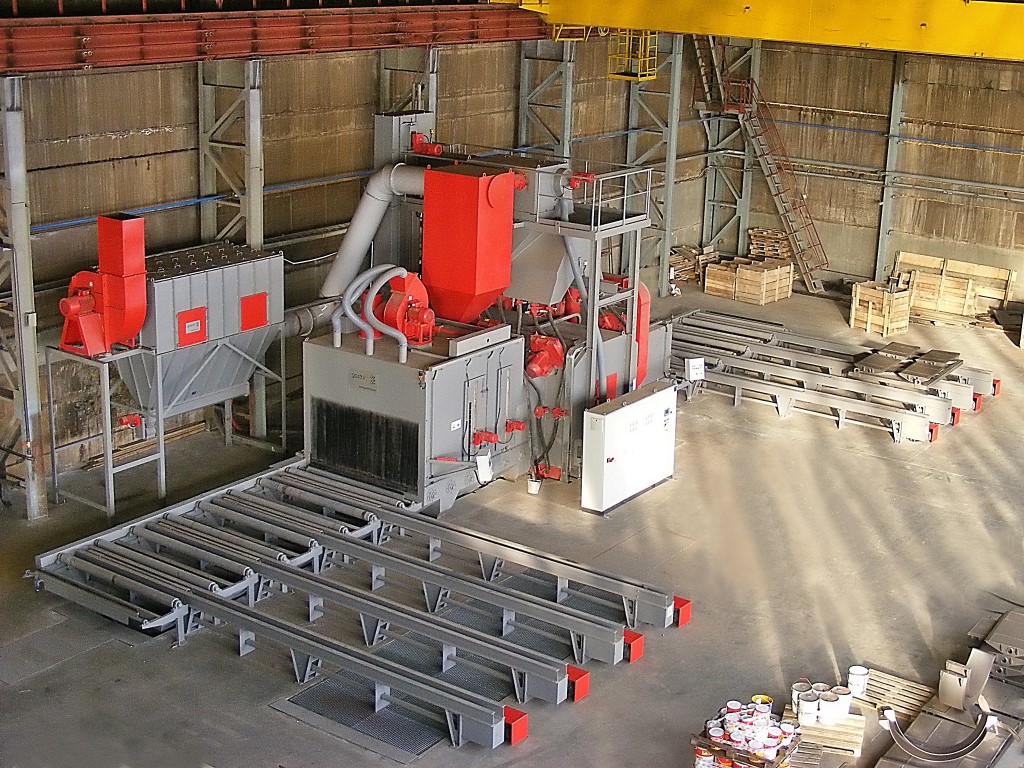

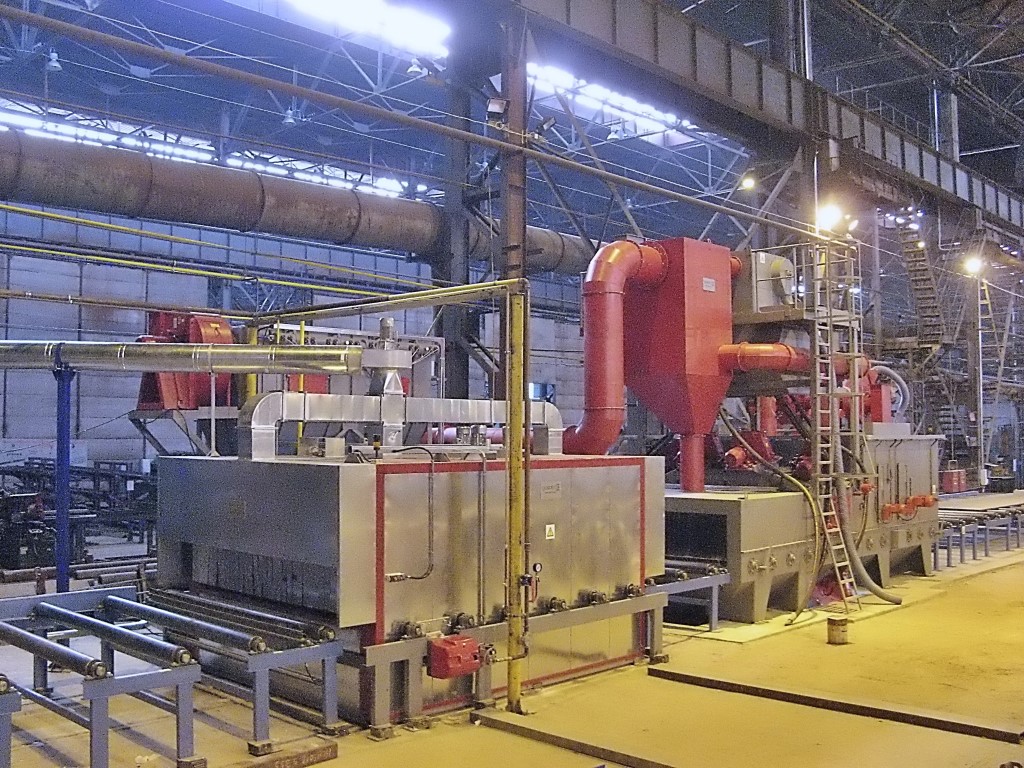

Roller conveyor shot blasting machine is primarily designed for shotblasting workpieces of larger dimensions, like steel sheets, profiles, beams and simple constructions. It is also possible to shotblast workpieces of shorter dimensions, which are loaded onto specially prepared housings or frames with mesh.

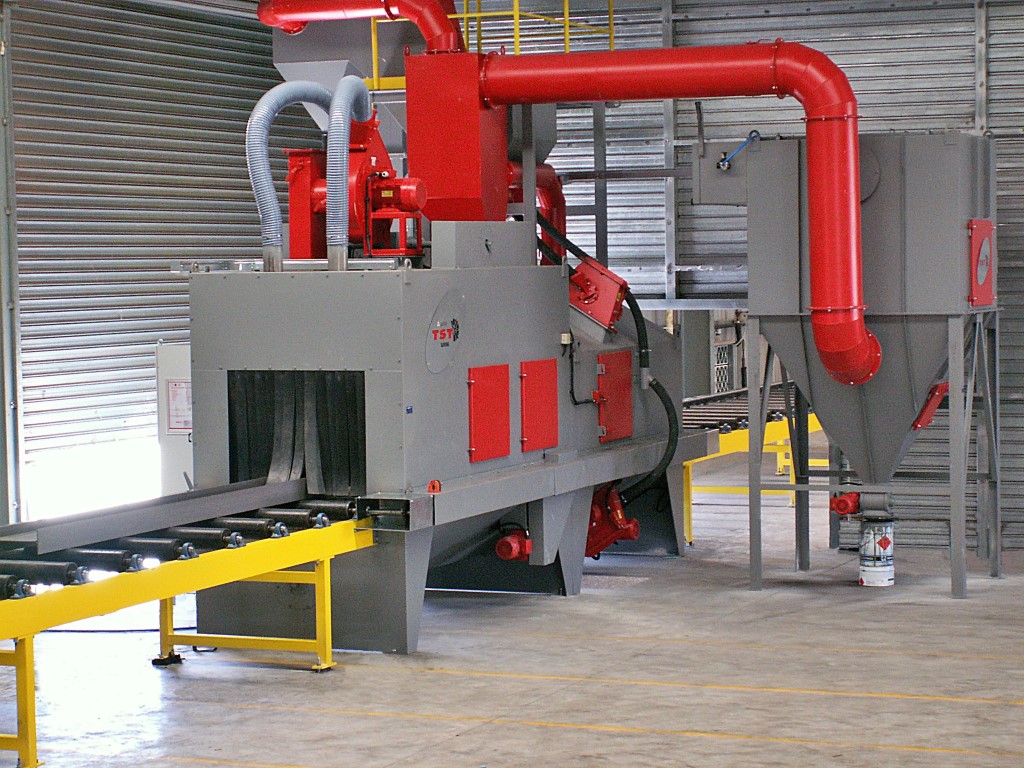

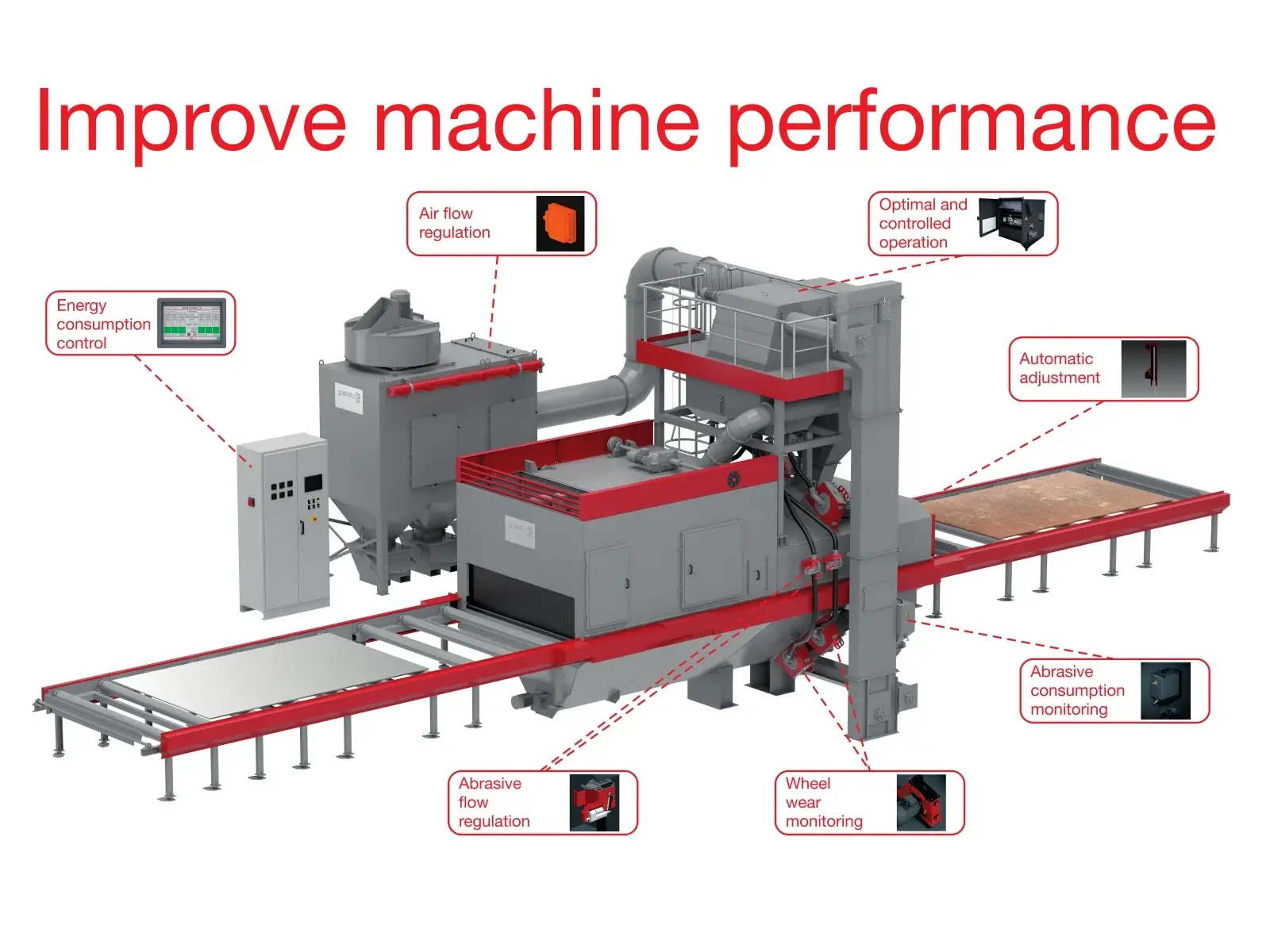

The workpieces are loaded onto a roller conveyor by means of a crane or forklift and transported through the machine. Depending on the process and the type of workpieces, the power of blasting wheels and the speed of roller conveyor are determined. All Gostol TST shot blasting machines have installed high efficiency ir blasting wheels. They are installed under a certain angle and have optimal positioning for less energy and abrasive consumption.

Roller conveyor shot blasting machine robust housing is protected with manganese steel shields, which are easy to replace and extend lifetime of machine. Series of rubber screens in entry chamber and exit cleaning chamber keep the abrasive inside the shot blasting machine. If any abrasive remains on the workpieces after the shot blasting process is completed, it is removed to a trough with quick height adjustable rotating brush and high-pressure fan. Screw conveyors, elevator and abrasive cleaner provide returning and continuous automatic cleaning of the abrasive.

Roller conveyor shot blasting machines may be built into highly productive lines for basic colour application, including drying chamber, automatic colouring chamber and drying tunnel.